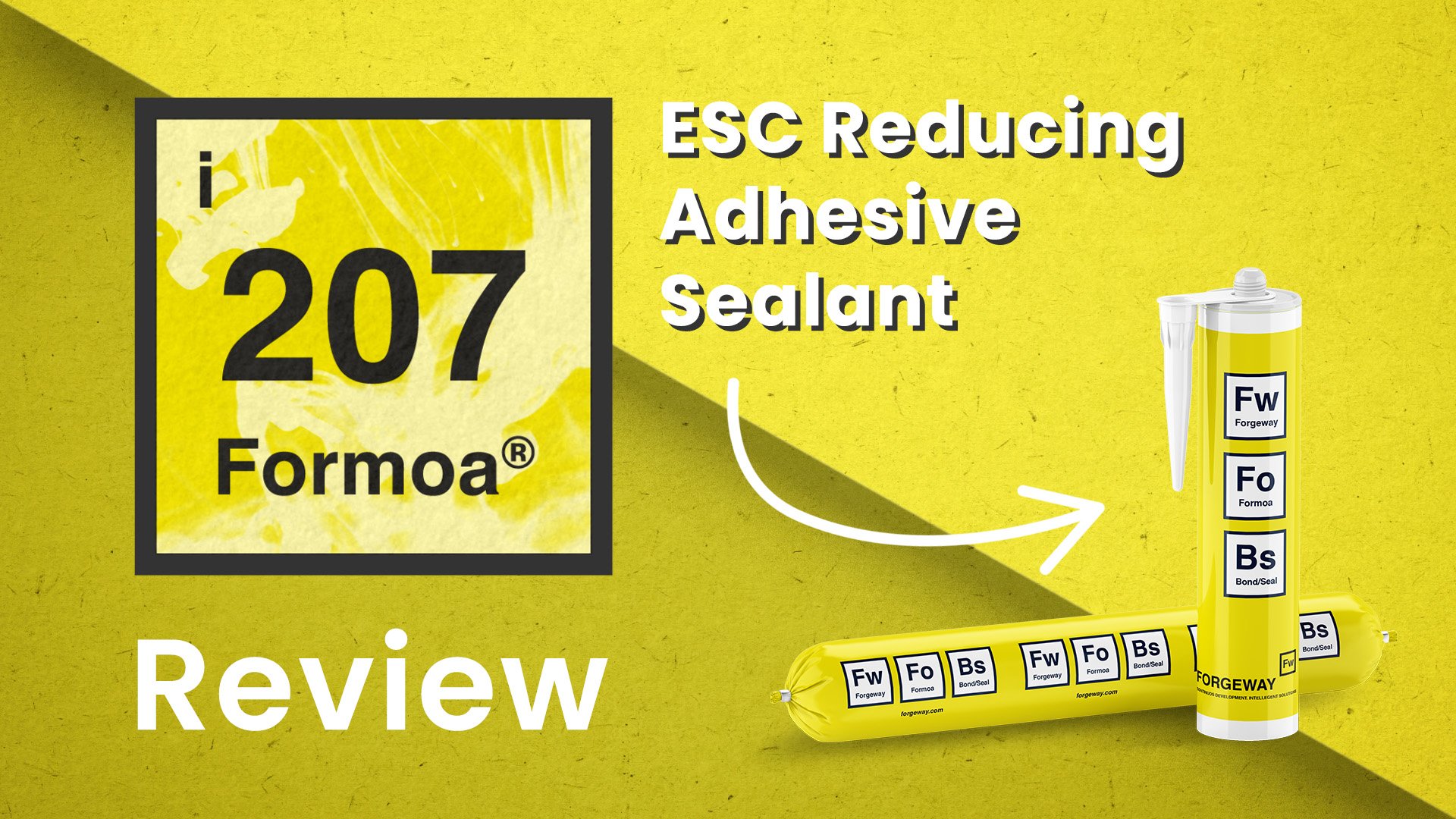

ESC Reducing Adhesive Sealant

Formoa® 207i

Formoa 207i is a single-component MS Polymer adhesive. It is designed for bonding applications that may require sealant properties to help prevent Environmental Stress Cracking.

• Helps reduce Environmental Stress Cracking

• High Flexibility

• Good strength

290ml Cartridge

600ml Foil Pack

Overview

Applications

The use of plastics has risen in recent years. However, some adhesives can attack the plastic and help speed up the environmental stress cracking process. Formoa 207i helps reduce the threat of the adhesive speeding up that process.

Due to the good strength and excellent flexibility characteristics, Formoa 207i can be used for both lightweight bonding and sealing applications. It's UV performance also means it will not degrade, even when exposed to harsh conditions.

Key features

How to use

(Lower temperatures will increase thickness)

Faq's

Whilst cannot share the exact ingredients, Formoa 207i has been formulated with specific components that ensure a non-aggressive bond. This helps ensure the plastic under stres isn't exposed to chemicals that will help speed up the cracking process. Read more about environmental stress cracking here.

Yes, once Formoa 207i is fully cured, it can be painted over. As there is no silicone based ingredients in Formoa 207i , it will not cause paint bubbling or cracking.

Once fully cured, Formoa 207i exhibits excellent resistance to a wide range of chemicals. Nonetheless, for specific chemical exposures, refer to the technical datasheet or conduct testing to ensure durability.

Formoa 207i bonds well with amorphous plastics (such as ABS, PVC, and Polycarbonate) as well as most metals, and composites. However, for low surface energy plastics (like PP, PE, or PTFE) or substrates with unique finishes, we wouldn't recommend Formoa 207i.

Its unique formulation, aimed at minimizing environmental stress cracking, makes it stand out. Many adhesives can bond plastics, but few ensure that the adhesive doesn't attack the plastic causing the cracking process to speed up.

290ml Cartridge

600ml Foil Pack

Close

Ready to purchase?

You can do so by purchasing directly from us or via one of our distributors

Unsure where to buy?

Read how to choose between manufacturer and distributor